Chemical Process Design

Minimizing drug development time through decision support systems.

Summary

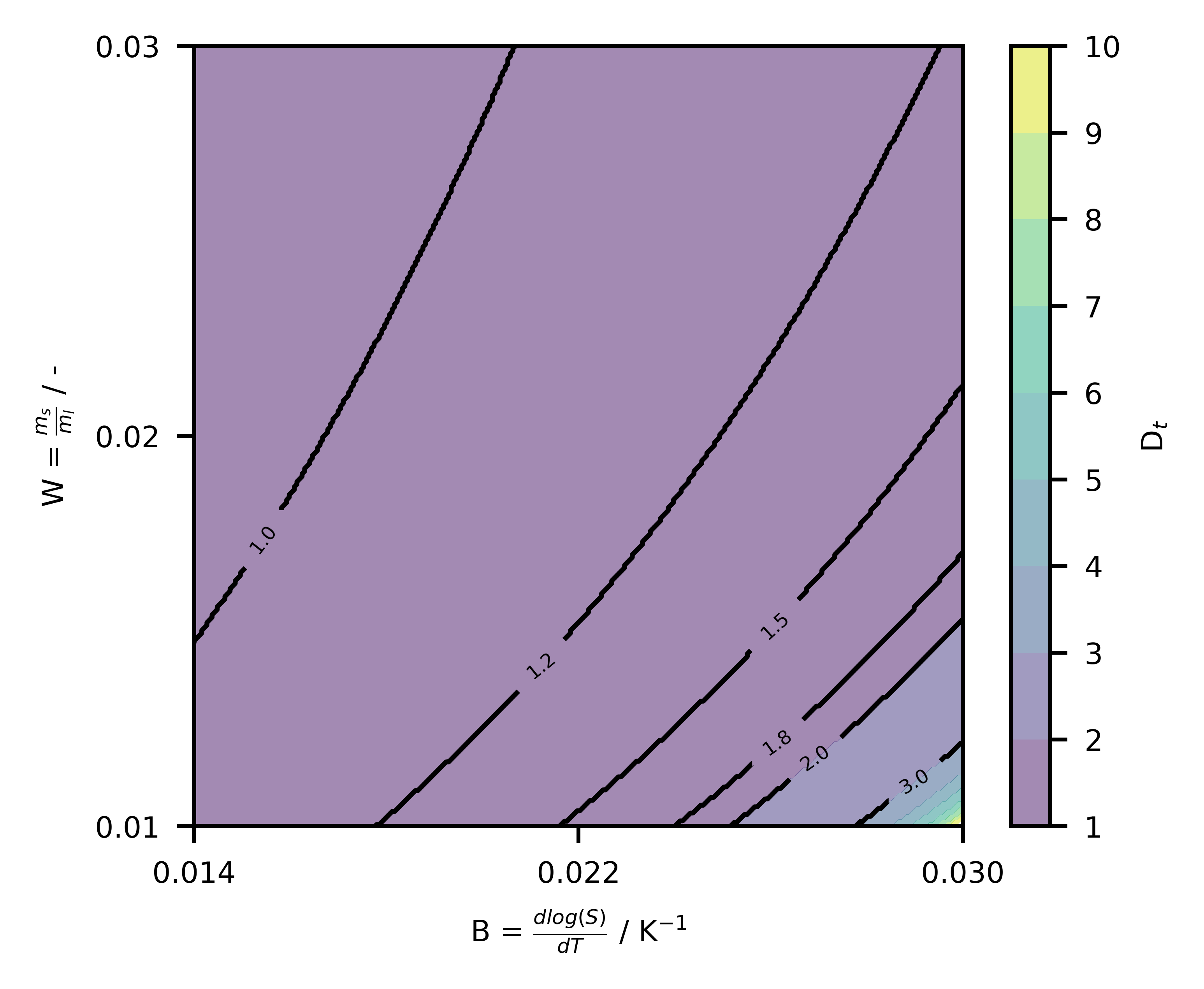

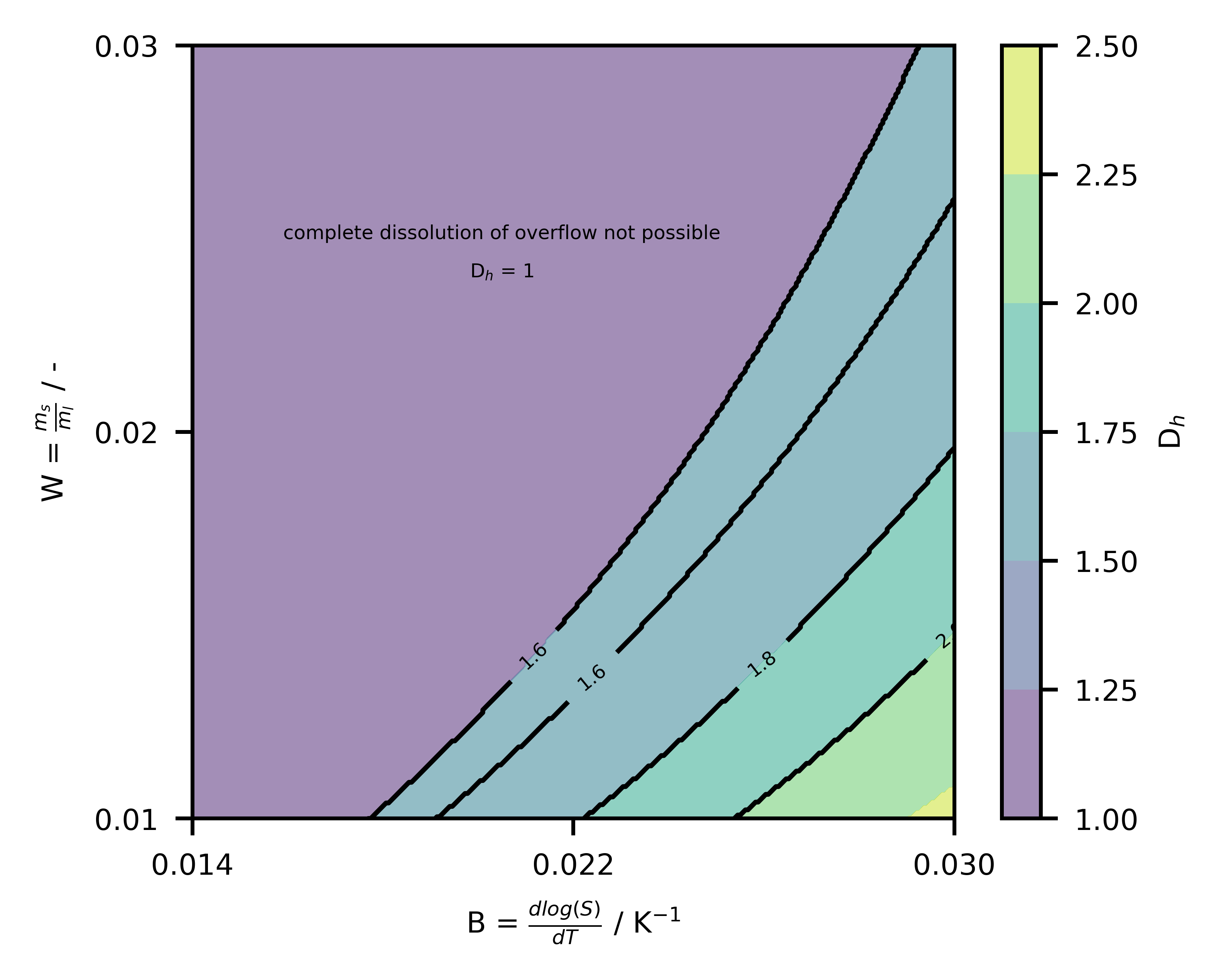

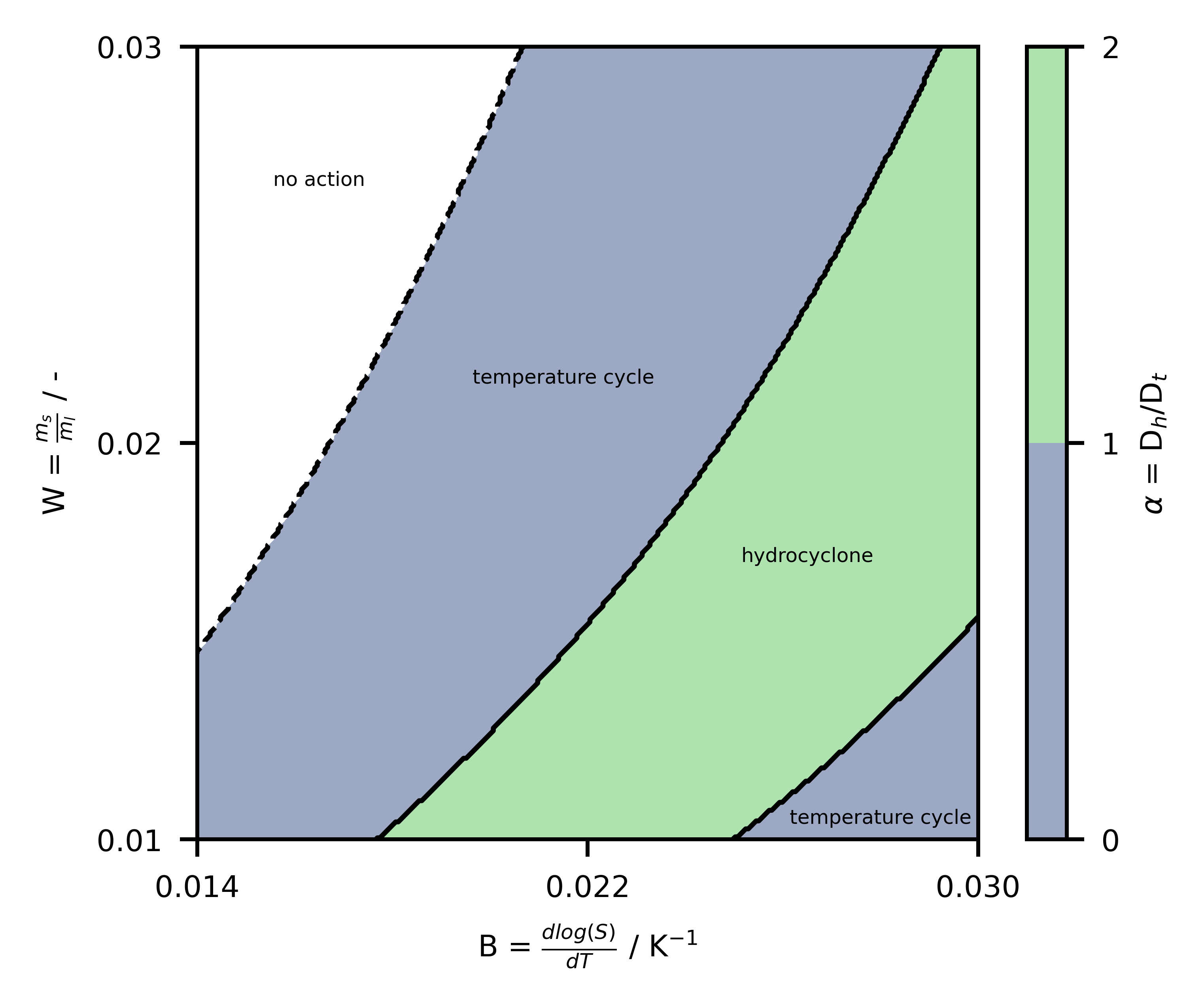

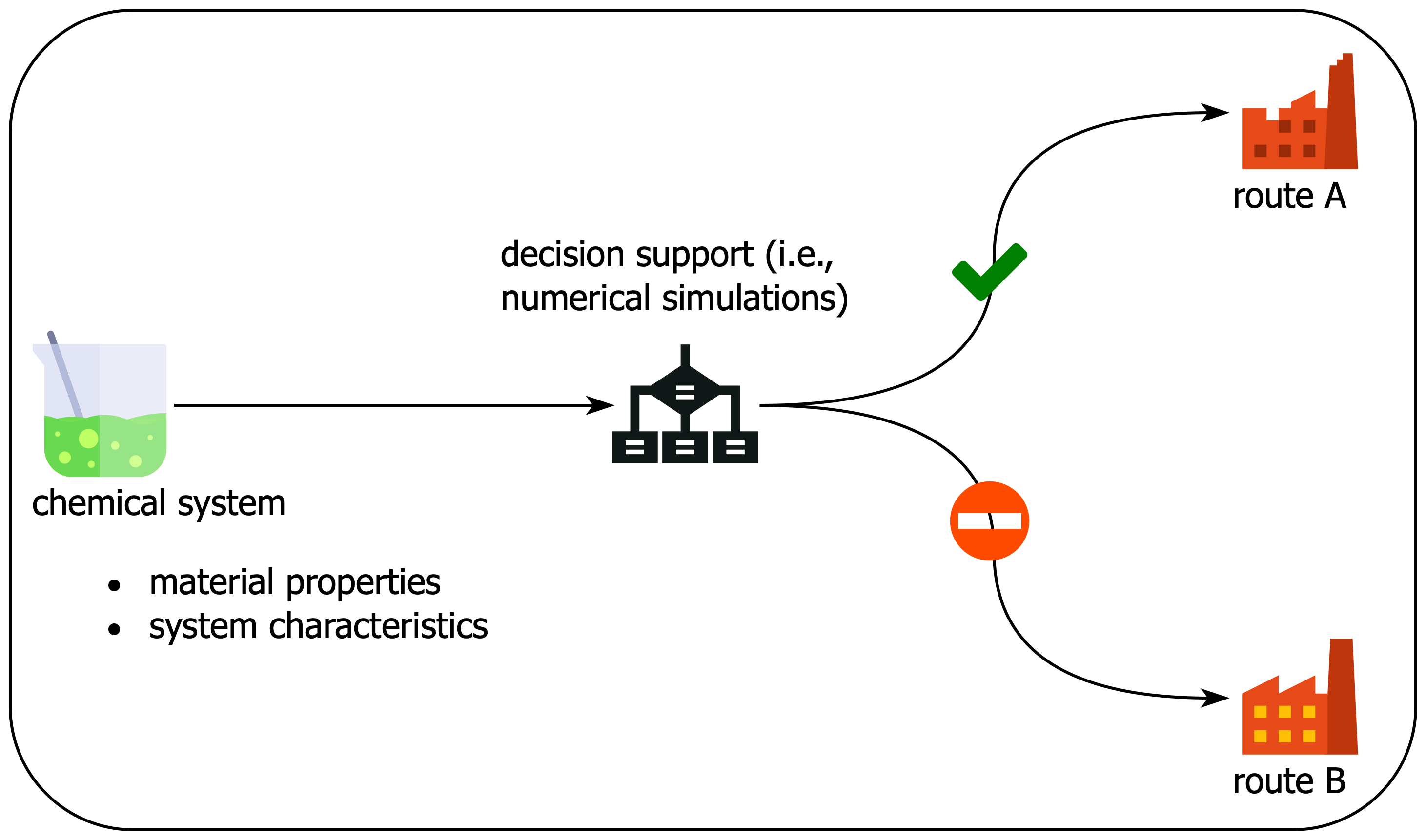

Drug development requires designing the appropriate manufacturing processes. This involves many decisions that are often made only through experimentation. However, this is time consuming and costly. To make the work more efficient, mathematical models and numerical simulations can be used instead. The prerequisite is that they adequately reflect reality. The characteristics (e.g., solubility and concentration) of the chemical system under consideration (e.g., a temperature cycle after crystallization) serve as input. By knowing the outputs under different chemical operations, one can judge which of them lead to the desired output (and which do not). It is then possible to decide which route is the most appropriate (Fig. 1).

I worked on such issues during my internship at Novartis in Basel. I put these things into software and defined metrics that could be used to make decisions.